Deltia.ai: Revolutionizing Assembly Line Productivity with AI

Deltia.ai leverages AI and computer vision to transform shop floor operations, boosting productivity and achieving significant cost savings. This innovative solution provides real-time insights, enabling proactive issue resolution and optimized workflows. Unlike traditional methods relying on manual data collection and analysis, Deltia.ai automates data gathering from shop floor operations, delivering actionable intelligence directly to your team.

Key Features

- Shopfloor Alerts & Reporting: Receive detailed reports on output, cycle time, and activity, with instant notifications of any deviations from expected performance. This proactive approach minimizes downtime and maximizes efficiency.

- Improvement Measures: Deltia.ai's AI algorithms analyze workflows to identify and prioritize areas for improvement, guiding your team towards impactful changes.

- Walking Routes Optimization: By analyzing movement patterns, Deltia.ai pinpoints inefficiencies in worker routes, suggesting optimized pathways to reduce wasted time and effort.

- Data-Driven Decision Making: Access comprehensive data visualizations and reports to make informed decisions, track progress, and demonstrate ROI.

Use Cases

Deltia.ai caters to diverse needs within the manufacturing sector. Its applications range from streamlining daily tasks for line managers to providing process engineers with data for long-term improvements. The system empowers teams to:

- Solve everyday shop floor tasks with ease: Quickly identify and address bottlenecks, ensuring smooth operations.

- Improve overall line workflow: Optimize walking routes and processes to enhance efficiency and reduce waste.

- Boost productivity and achieve savings targets: Leverage data-driven insights to make informed decisions that drive significant improvements in productivity and cost savings.

How Deltia.ai Works

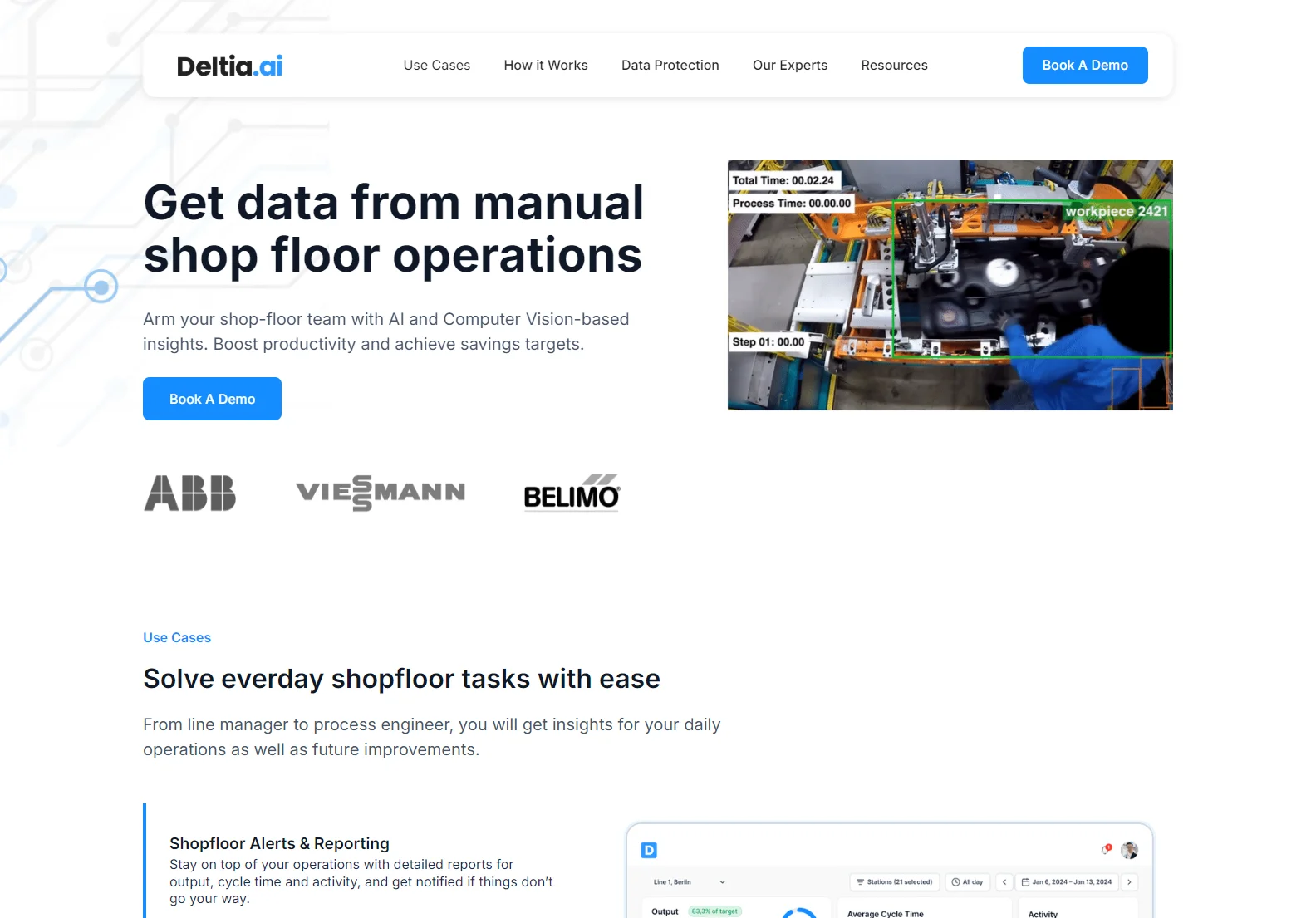

Deltia.ai seamlessly integrates into existing shop floor operations. Through a combination of AI and computer vision, the system collects data from various sources, analyzes it in real-time, and delivers actionable insights to users. This process involves:

- Data Acquisition: Sensors and cameras capture data on various aspects of the assembly line.

- AI-Powered Analysis: Deltia.ai's algorithms process the data to identify patterns, anomalies, and areas for improvement.

- Actionable Insights: The system generates reports, alerts, and visualizations, providing clear guidance for optimizing workflows.

- Continuous Improvement: The system continuously learns and adapts, providing increasingly accurate and relevant insights over time.

Data Protection

Deltia.ai prioritizes data security and privacy. We employ robust security measures to protect your data, complying with all relevant regulations. Our commitment to data protection ensures that your sensitive information remains confidential and secure.

Comparisons

Compared to manual data collection and analysis, Deltia.ai offers significant advantages in terms of efficiency, accuracy, and time savings. Unlike other AI-based shop floor solutions that may lack real-time capabilities or comprehensive reporting, Deltia.ai provides a holistic and integrated approach to optimizing assembly line operations.

Conclusion

Deltia.ai is a powerful tool for manufacturers seeking to enhance productivity, reduce costs, and improve overall operational efficiency. Its AI-powered insights empower teams to make data-driven decisions, leading to significant improvements in assembly line performance.